Linear motion systems boost railway maintenance safety and efficiency

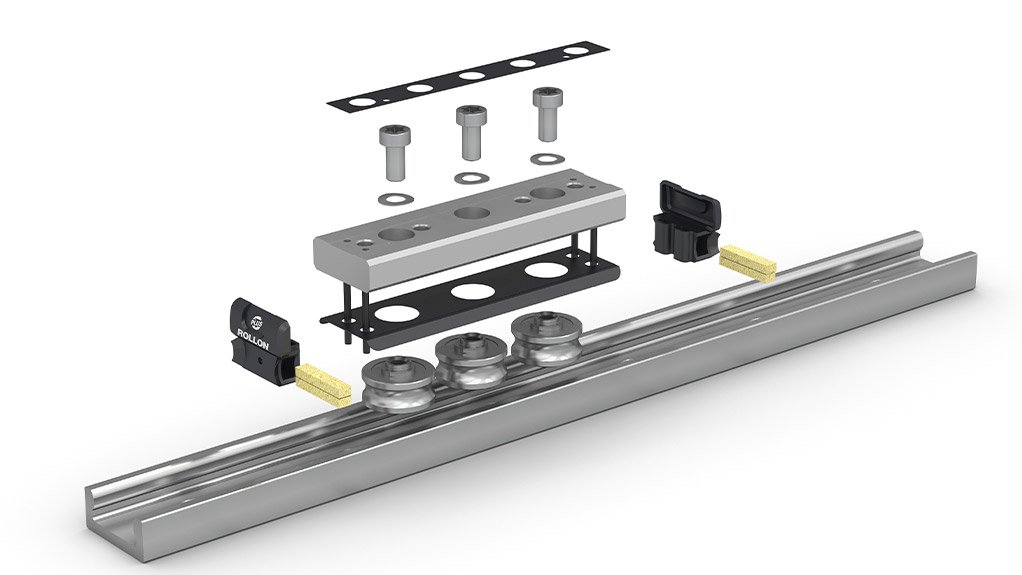

ROLLON SYSTEM The integration of Rollon’s Compact Rail system into the maintenance of locomotives demonstrates how advances in mechanical design deliver significant benefits across safety, cost and efficiency in the railways sector

Industrial solutions provider BMG has expanded its portfolio of motion control technologies with the introduction of Rollon linear guidance systems, designed for high efficiency in many industries, including the Southern African rail sector.

These advanced systems – developed by Rollon, a member of The Timken Company – are specifically engineered to deliver high-performance motion solutions in demanding environments, including railway infrastructure and maintenance applications.

The Rollon Compact Rail system, which has shown success in European maintenance locomotives, offers a robust solution that enhances both safety and functionality. By facilitating smooth manual adjustment of onboard equipment, such as seating mechanisms, the system enables technical teams to improve lateral visibility and react more effectively to track-side conditions during maintenance operations. The system also allows operators to slide across to observe both sides of the locomotive, without relying on powered components, thereby reducing failure risks and improving operator performance.

BMG’s Linearway and ball screw product specialist Leon Koekemoer states, “Rollon’s linear motion guidance solutions are built to accommodate misalignment and can be mounted on standard fabricated steel, without the need for precision machining. This makes them ideal for heavy-duty and mobile environments [. . . ] In addition, the telescopic rails within the range offer market-leading load capacities, ensuring long-term reliability.”

He adds that Rollon’s approach is based on delivering modular and configurable motion systems that integrate easily into various industrial structures. For railway operators, this translates into reduced fabrication costs and greater flexibility in vehicle interior layouts. “Beyond seating, the same principles are being applied to tool storage, inspection bays and other areas, where adaptable linear movement can contribute to better ergonomics and workflow.”

A notable feature of the Compact Rail TLC43 and ULC43 models is their ability to perform under harsh operating conditions, including vibration, dust and shock.

These rails use rollers rather than balls, providing smoother and quieter motion, while withstanding accelerations of up to 3 g and functional loads of 150 kg. This solution is suitable for both new installations and retrofitting in mobile maintenance units, where ease of integration and minimal electronic control requirements are advantageous.

In addition to maintenance in the railways sector, Rollon Compact Rail – with its self-aligning and compact design – is used in diverse industries, including industrial machines, materials handling, packaging, aerospace, electronics, food and beverage, machine tools, special vehicles, robotics and automation and healthcare.

As part of the extensive Timken portfolio, Rollon products benefit from global standards in quality assurance and supply chain integration. BMG’s appointment as the authorised distributor in Africa ensures that the local market has access to both the product range and the necessary local support, including technical selection, condition monitoring and retrofit consultation.

BMG supports industry with motion control solutions that combine performance, durability and ease of use. The Rollon system enhances this offering, particularly for rail customers seeking dependable and efficient components for fleet upgrades and new builds.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation